We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What is a Forged Billet Wheel

What Is a Forged Billet Wheel?

1 - A forged billet wheel begins as a solid piece of aluminum known as a billet.

2 - The billet aluminum is forged into a plate like form using extreme pressure and heat to form a raw forging, known as a rim center.

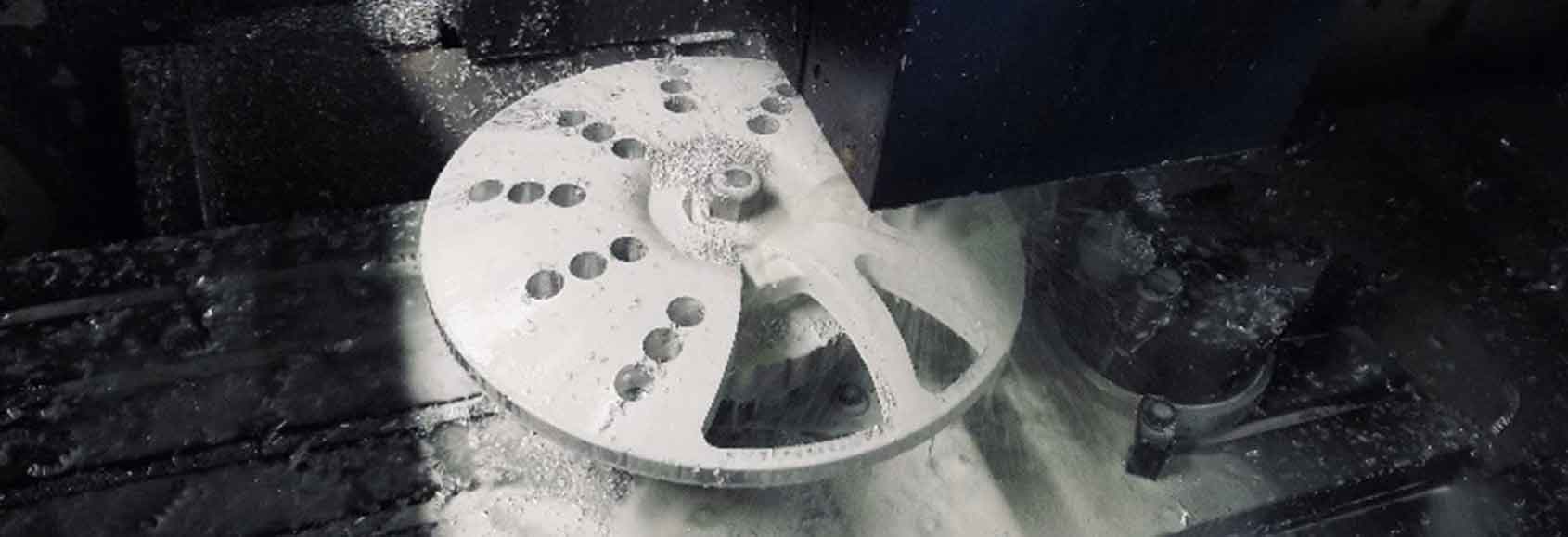

3 - The forgings are turned on a CNC lathe and machined on a CNC Mill to form the desired style of wheel.

4 - Once the forged billet center is machined and finished it is then assembled in a spun aluminum rim.

The intense pressure that the billet goes through during the forging process causes the metal to be less porous compared to cast wheels. Forged billets wheels are known to be stronger than cast wheels due to the grain refinement which is caused by the thermal cycle and forging process. Forged billet wheels are also known to be less prone to oxidation and corrosion.

There are three types of forged billet wheels. One piece monobloc wheels, two piece wheels and three piece wheels.

1 Piece Construction:

The entire wheel is machined from one piece of billet aluminum, known as a monoblock. Mono meaning one & block meaning it was created from one block of forged aluminum. The monoblock is machined into a wheel and is usually the lightest in weight, but it is limited to a small amount of widths and offsets.

2 Piece Construction:

The wheel is made out of two separate sections, the center and the rim. The forged aluminum center is machined to form the design of the wheel, and is welded or bolted on to the rim to form a complete wheel. 2 piece wheels are available in multiple sizes and offsets.

3 Piece Construction:

These wheels are made with 3 separate parts. The forged billet center, the outer rim and the inner rim. All three sections are bolted together to form a complete wheel. 3 piece wheels offer the most available widths and offsets, due to their construction method. However they tend to be the most expensive because of the labor required to assemble the wheel.

Pro wheels offers the top forged billet wheels in the market.