We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

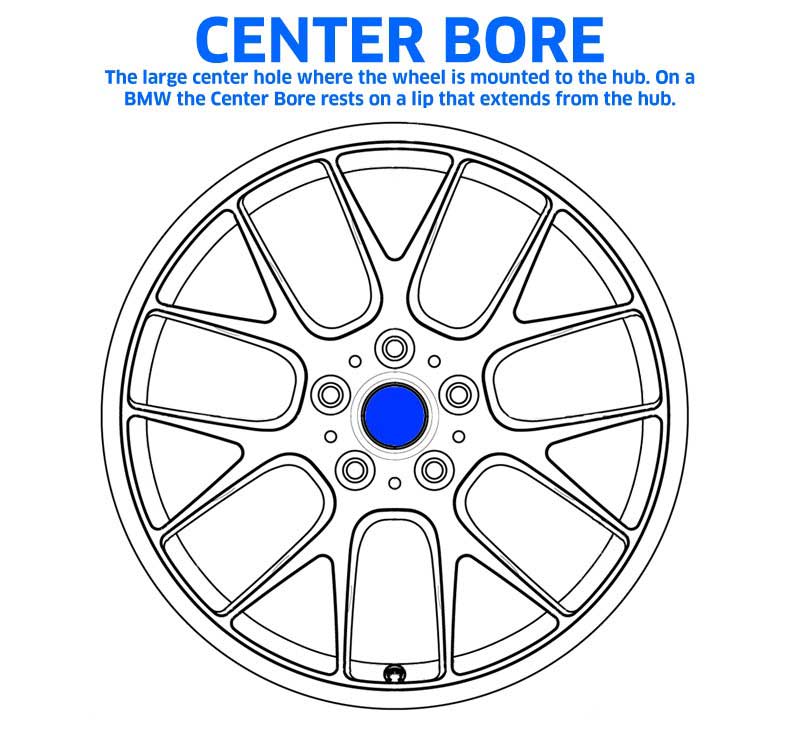

Centerbore

Billet Wheel Center Bore

The center bore of a billet wheel is the machined opening on the back of the wheel which centers the wheel properly on the hub of a vehicle. The center bore is where the spigot fits through. Center bore is also known as spigot size and the diameter of this hole is usually measured in millimeters. This hole matches the hub exactly so the wheels are precisely positioned during the lug nut torquing process. Having the billet wheel precisely centered on the vehicle’s hub as it is being mounted reduces the chance of a vibration while the car is in motion. This vibration is dangerous and leads to an uncontrollable car at high speeds. This is why it is extremely important to ensure that your new custom billet wheel has the proper measurements.

To measure your center bore you will need the following:

- 12-inch steel rule

- 4-inch combination square

- Calculator

Once you have acquired the proper tools follow the steps listed below:

1. Set your wheel hub side up on a flat surface

2. Press the zero end of a steel rule on one side of the center bore

3. Set one side of the 4-inch combination square blade against the inside of the center bore, making sure that it is opposite of the zero end of the steel rule

4. Take note of the number that is found on the steel rule that aligns with the combination square blade that is set against the center bore. That number is the diameter of the center bore

5. You will need to convert the measurement to decimals by entering the fraction into the calculator. Once you have converted round to the nearest hundreth

If there is a case where the center bore is larger than the hub on your vehicle it is possible to use hub centric rings (spigot rings). These rings are sold and added onto the billet wheels which allows the wheels to adapt the size of the centre bore. Hub centric rings do not work if the center bore is smaller than the hub on your vehicle, if this is the case then the only way the billet wheels could be made to fit would be to machine the center bore. This is an expensive process.

Some wheels are non-hub centric by design; these are known as lug centric wheels. Our custom forged billet wheels are not hub centric by design which therefore makes them lug centric. With our custom forged billet wheels, it is critical to torque the lug nuts or bolts with the vehicle on jack stands, off the ground. This allows the nuts or bolts to center the wheel and torque down without the weight of the vehicle pushing down and setting them off center.